Print

Print

Orders Scheduled Until the Third Quarter: Leshan Kangbeide New Materials Accelerates in the Southwest Wood - based Panel Industry

2025/04/08 15:00 Origin:cced.cn

On April 7, the production workshop of Sichuan Kangbeide New Materials Co., Ltd. located in Wangcun Town, Jingyan County was filled with the roar of machines, and the fully automated production line was operating at full capacity. As an innovative small - and - medium - sized enterprise and a key investment - attraction project in Jingyan County, the company achieved an output value of 360 million yuan in 2024. Its product orders are scheduled until the third quarter of 2025. In the first quarter of this year, it produced approximately 90,000 cubic meters of super - strong particleboard and FOSB home panels, with an output value of approximately 94 million yuan. These remarkable figures mark the company's important position in the wood - based panel industry in the southwest region.

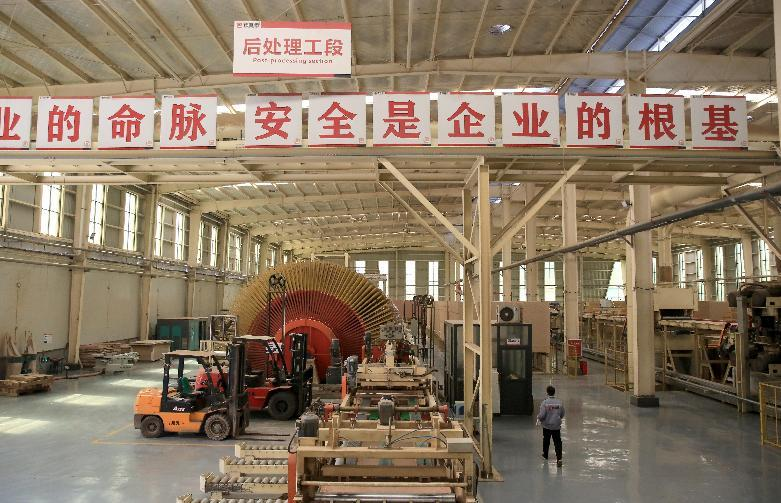

Roaring Machines and a Production Workshop Operating at Full Capacity

Walking into the company's workshop, one can hear the deafening roar of machines. The forklift transports raw materials such as tree branches to the conveyor belt for processes like wood drying, cutting, and chipping. In the production monitoring room, rows of monitoring displays show the production data of the equipment, and workers monitor the working status of the fully automated equipment through computers. Each fully automated production device is operating at full capacity, and several workers are patrolling and inspecting on the production line in the workshop. The equipment on the production line automatically completes more than a dozen processes, including the layered laying of panel raw materials, drying, continuous flattening, cutting, and panel packaging. Then, workers use forklifts to transport the packaged panels to the warehouse for loading and shipping.

It is reported that products such as the company's super - strong particleboard and FOSB home panels are widely used in fields such as customized home furnishings. They are mainly used in industries and fields such as customized home furnishings, integrated wardrobes, kitchen cabinets, TV cabinets, and office furniture. The products are mainly sold to major domestic markets such as Chengdu, Chongqing, Xi'an, Guangdong, and the Yangtze River Delta region. The company also custom - makes high - end home panels for domestic big brands such as QuanU and Pearlmobile, and is favored by merchants, with orders maintaining a steady growth.

Investing Heavily in R & D to Build Core Competitiveness

"Sichuan Kangbeide New Materials Co., Ltd. is located in Wangcun Town, Jingyan County, covering an area of 200 mu with a registered capital of 60 million yuan. As a "chain - strengthening and chain - supplementing" project introduced to Jingyan County from Shandong by the Jingyan County Party Committee and the county government, its total investment of 800 million yuan is planned to be implemented in two phases. Since construction started in June 2022, 480 million yuan has been invested, and five standardized workshops (about 25,000 square meters) have been built, and a production line with an annual output of 300,000 cubic meters of super - strong particleboard and FOSB high - end panels has been put into production," introduced Gong Lijun, the manager of the Personnel and Administration Department of Sichuan Kangbeide New Materials Co., Ltd.

It is reported that the company has introduced internationally advanced equipment such as the 42.5 - meter continuous flat press of Suzhou Sufuma of China National Machinery Industry Corporation, the ring - type chipper of German PALMAN, and the Jieqi Mark Energy Center, and is equipped with a zero - discharge wastewater treatment system and a VOCs purification device, forming a fully - process intelligent production line. It realizes full - process automation from log processing to product packaging. Its flagship product, the FOSB high - end panel, is made of 100% Chinese fir raw materials and MDI formaldehyde - free glue, and its environmental protection level reaches the national ENF standard. It uses fully automated three - group sanding for shaping, and the surface of the panel reaches the flatness of medium - density fiberboard, which can meet various finishing materials and processing techniques, such as high - gloss impregnated paper laminating, flat - pasting PET, and UV - curing of paint, with flexible finishing and wide applications.

Cost Reduction, Efficiency Increase, and Remarkable Results in the Green Circular Economy Model

It is understood that the company has constructed a "three - waste resource - based" system. The wood processing residues are converted into clean energy through a biomass boiler, replacing 12,000 tons of standard coal annually; the sanding dust is made into fuel rods after cyclone separation; and the production wastewater has a 95% reuse rate after in - depth treatment. In 2024, it was rated as a "circular economy demonstration unit" in Sichuan Province, and its environmental protection practices were included in the "White Paper on Green Production in the Wood Industry in Southwest China".

"The first phase of the project provides more than 200 jobs, with local employees from Jingyan accounting for more than 70%," Gong Lijun said. In 2024, the company achieved an output value of 360 million yuan. In 2025, the company will focus on refined management, quality improvement, and new product research and development. The annual planned target output is 360,000 cubic meters, and the planned output value is expected to exceed 450 million yuan. (Text/Photos: Liu Xiaoli)

Copyright © CCEDN.COM.CN. All Rights [京ICP备2024049485号-1] Tel: 0086-10-88820521